Gadot Belgium starts cooperation with LUMINUS and City of Ghent for construction of wind turbine

Tuesday, October 26, 2021 – Luminus will build a wind turbine on Gadot Belgium’s premises at the Mercatordok in Ghent port in 2022. Through the municipal holding Zefier, the city of Ghent is also investing in the wind energy project. The city’s proceeds flow into a rolling climate fund. This provides cheap and long-term energy loans to all Ghent citizens who want to renovate their homes in a climate-friendly way.

Mercatordok wind turbine project

In 2022 a wind turbine will be erected at the Mercatordok in the port of Ghent on the land of Gadot Belgium. The site in question has a very large wind potential and is located in the heart of the port of Ghent, far from the surrounding residential areas.

It will be a wind turbine with a rotor diameter of 138 m and a mast height of 111 m. The wind turbine will produce more than 10 GWh per year, accounting for the annual energy consumption of 2,900 Ghent households. This will save 5,300 tons of CO2 (eq.) compared to the average Belgian electricity mix. This saving is comparable to the emissions of about 500 diesel cars (1). Gadot Belgium will use about half of the produced green electricity locally on its site and will thus make its activities significantly more sustainable.

The project will pay extra attention to birds. A bird radar will be installed nearby to monitor the flight movements. At the most sensitive moments, the turbine will be shut down to ensure the safety of the birds.

The City of Ghent has a 49% share in the wind turbine through a guarantee. Luminus is participating for 51%. The city’s proceeds will go to a rolling climate fund. This provides energy loans to help Gentenaars reduce their energy consumption more quickly and to allow them to invest in renewable energy. Moreover, people with lower incomes can now get a cheap loan to tackle the basic quality of their homes. The wind turbine therefore benefits all inhabitants of Ghent.

Wim De Windt, CEO Gadot Europe and Managing Director Gadot Belgium:

“Gadot Belgium is extremely proud to be able to welcome the first wind turbine with participation via Zo-Fier to its terminal at North Sea Port by the city of Ghent and for the people of Ghent. With environmentally friendly energy for all its processes, Gadot, which specializes in chemical production, storage and filling activities, is taking an important step in its growth ambitions to build up a sustainable chemical cluster at a superb location in port of Ghent. Gadot is happy to join forces with Luminus as a strategic partner.”

Municipal participation in wind projects

The wind turbine will be owned by Zo-Fier nv, a joint subsidiary of Luminus and Zefier that focuses on the development, construction and operation of renewable energy projects.

Luminus and Zefier want to involve local residents as much as possible in these renewable energy projects. Zefier is already active in 168 municipalities, representing 4.2 million inhabitants or 65% of the Flemish population. Through Zefier’s participation in Zo-Fier, Zefier’s municipal shareholders will now be able to participate in Luminus’ wind projects in their municipality.

Grégoire Dallemagne, CEO of Luminus:

“As the number one in wind energy in Belgium, we want to build a CO2-neutral energy future where protection of the planet, well-being and economic growth are reconciled thanks to electricity and innovative services. For this we need both citizens and governments. Thanks to Zo-Fier, we can involve them even more in our renewable energy projects. Only together do we make a difference.” The fight against climate change

For Luminus, the fight against climate change is a work in progress every day. The company has been investing in the production of renewable energy for more than 60 years. More than 26% of its energy production comes from renewable energy sources of Belgian origin. Luminus has been betting on wind energy since 2001 and its wind farm is experiencing constant growth. With its 249 wind turbines, the company has an installed capacity of 630 MW, equivalent to the consumption of approximately 344,000 families.

Chemist Gadot knocks on DFDS’ door for inland navigation Ghent-Antwerp

Tank terminal operator Gadot Belgium recently started working with neighbor DFDS Seaways for the export of chemical products by barge from Ghent to Antwerp. DFDS takes care of the entire route, including container collection, weighing and customs matters.

The transport of the containers with chemical products by inland navigation between Ghent and the Port of Antwerp is a first for both DFDS and Gadot. “Because of the proximity,

Gadot and DFDS are neighbors, it is almost logical that they will join forces with us for the barge transport of their export containers. We already had regular sailings from Ghent to Antwerp and Rotterdam for local industry and automotive. For this we chartered We charter a ship from the Dutch company Honkoop Barging. In Antwerp we call at all quays. Gadot is a new client for whom we organized the first deepsea export shipments of chemical products.

We take care of the entire process: from picking up the containers to weighing them and weighing and the customs formalities. The chemical products are in Intermediate Bulk Containers (IBCs) that are loaded into shipping containers. We want to make this a regular traffic”, explains Frédéric De Vreese, business development manager at DFDS Seaways.

Onestopshop

Ludwig De Bock, business manager export at Gadot Belgium, part of the Israeli Gadot Group, speaks of a milestone for the company. “This is important for the future. More and more attention is being paid to the ecological footprint. Until now, the export containers went by road. We are in the start-up phase and have had the first delivery of ten containers via inland shipping. We want to expand that further and work with the customers to see how we can generate more and more exports and how we can improve their supply chain and our service to the customers.

Gadot is originally a toll blender, but we also offer chemical filling and packaging capabilities in IBCs. We want to manage the customers’ entire supply chain and function as a one-stop shop, also for other companies here in the region,” concludes De Bock.

Gadot and DFDS start chemical cluster collaboration

Gadot and DFDS start chemical cluster collaboration

On Friday 21st of August, Gadot Belgium expanded its ambition for a chemical cluster in Ghent and set up a partnership with the adjacent DFDS terminal.

For the export of chemicals, DFDS provides the connection by container barge to deep sea terminals in Antwerp.

The Gadot production site is perfectly located to use the DFDS terminal. This ensures a very short pre-carriage and a maximal green print. Due to smooth communication with all parties involved – including customs, forwarder, and barge operator – the first shipment is an absolute success and chemical exports are organised on this basis from now on.

It was the first shipment for both parties in this new partnership. For Gadot it was the first time they used the inland shipping connection for their global deep sea export. In this way, Gadot responds to the social importance of reducing the ecological footprint throughout the entire supply chain.

For DFDS, on the other hand, it was the first experience with Gadot as a customer and an extension of the services towards the chemical market.

With this first shipment, Gadot and DFDS are starting a partnership in which their logistics flows and activities are also being investigated and projects are further developed for the future.

www.dfds.com/en/freight-shipping/terminal-services/ghent-terminal

Gadot Ghent seeks growth

A lot is happening at Gadot Belgium,formerly known as VLS-Group Ghent. Apart from the recent name change – as part of a larger rebranding and restructuring of the Gadot Group’s setup of facilities and activities in Europe – a new management team was installed in July 2019, led by newly appointed CEO Wim De Windt.

Gadot expands its terminalling activity in North Sea Port

In the middle of an economic and social landscape that is rapidly being changed through the corona impact, Gadot is ready to react and stand its ground.

Gadot had prepared a plan to balance its manufacturing activities with additional storage and terminalling that was ready for roll-out early Q3. This was just in time to help a range of customers that were anxiously looking for additional storage capacity for such chemicals like biofuels and ethanol.

With over 10.000 m³ of additional storage, and more in the pipeline, Gadot reconfirms its position in North Sea Port as a reliable and multimodal tankstorage terminal, right in the heart of Europe. It has been a while, but we’re back in full force!

A new Chapter begins: Gadot becomes a player in the European chemical distribution scheme.

Under the new management, Gadot Belgium made a long term ambition – Gadot becoming a player in the European chemical distribution scene, a reality.

Gadot Group had formulated a clear focus and strategy to grow their chemical distribution business in Europe.

Geographical location, supply routes, modes in and out, presence of assets and utilities, as well as synergies with other activities on-site made Ghent plant an excellent choice to set up a chemical distribution warehouse location.

Wim De Windt, CEO for Gadot Europe, states: “This project is part of our strategy to transform the plant in Ghent into a motor of sustainable growth in the heart of the European chemical scene. Through scaling, using our strengths and expertise in chemicals handling, we broaden our commercial footprint and our activity base. Gadot’s customers will benefit from our location, from the Group’s extensive experience in chemical distribution and logistics and from our focus on service, safety and excellence.”

After almost a year of preparation and over 1.8 million of investment, on April 28th 2020 the first chemical tanker docked into the Ghent jetty and supplied a first parcel of 2500 MT of caustic soda. This marked the official start of chemical distribution in Europe.

More products and tanks are being built, automatic in-line dilution equipment has been installed and several 1000s of tonnes of chemical products have been supplied in the months following April 28th out of terminal in Ghent.

This marks an important milestone in the history of Gadot Europe and an exciting future for all our customers looking for a reliable and safe home for their chemical distribution needs.

Gadot develops Gadot IoT: its digital proprietary technology to manage and optimize storage capacity

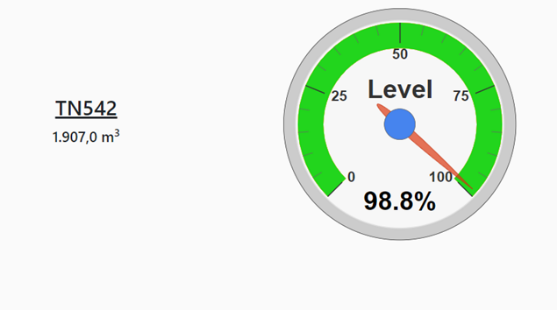

As part of Gadot’s continuous improvement program and in line with our trend for digitization, a new tool was developed that allows continuous on-line monitoring of chemical volumes and tank capacity utilization.

The tool, that was baptized Gadot IOT and was developed with our preferred partner Telforce, allows to have a continuous update view on tank capacity, allows statistical analysis and makes all data related to the products and tanks visual through dashboards.

“IOT provides a unique tool to optimize our asset utilization and improve our safety, compliance and efficiency at the same time” states Gadot Europe’s CEO Wim De Windt.

Gadot invests in new automated filling lines

Gadot Belgium made another significant investment of 2 million EUROs in a set a new automated and semi-automated filling lines for classified and non-classified materials. The new lines complement the already existing filling capabilities of the site in Ghent and are needed to cover Gadot Belgium’s growth ambitions for the next few years.

Early January, testing was completed and commissioning of the new lines was completed.

The filling lines are integrated into a new warehouse setup, thus strongly reducing forklift traffic. Whenever possible, transfers are done by a conveyor system and a new automated transfer shuttle that is programmed to move drums from one location to another. This robotic transport system has its own data storage that registers what product it is transporting. The new filling lines set up is completed with a new palletiser that automatically handles various pallet types.

Through these new high performance filling lines, Gadot Belgium now has a combined capacity of 90.000 m³ of annual filling.

Opening of new production hall in port of Ghent

With the cutting of a ribbon, the new production hall of GADOT Group in Ghent has been opened. The international chemical company invests 4.3 million euro in its department in the port of Ghent. GADOT Group built a new production hall to increase the production of viscosity improvers. These are substances that determine the thickness of oil.

GADOT Group opens brand-new production hall in port of Ghent

On Tuesday, 12 July 2016 the chemical logistics company GADOT Group opened a new production hall in port of Ghent for the production and storage of viscosity improvers. With this investment, GADOT Group wants to attract even more international customers and make itself better-known. Ghent Port Company is delighted that one of the driving forces continues to invest in the port.

The investment amounts to 4.3 million euros. With this money, GADOT Group is building a new hall of 1,400 m² on its company grounds. That hall consists of a production hall of more than 400 m² (+ 200 m² extra on a platform) and a storage hall of almost 1,000 m².

The storage hall will be used for the storage of packed raw materials and the installation of two new production units for viscosity improvers. One of those units will be used exclusively for a European customer. The second one will be offered worldwide to various customers. A space has been reserved already for a further expansion to four units.

At this moment, also two new storage tanks are being built having a capacity of 100 m³. In the future, they will be supplemented with six extra storage tanks of 100 m³. The total storage capacity will then amount to 100,000 m³. The investment will generate 4 additional jobs for operators.

This investment and the expansion possibilities together will enable GADOT Group to produce more and also store more products but mainly to attract more customers from all over the world.

For the desired fluidity of liquids

GADOT Group is a specialist in providing integrated logistics solutions, which include chemical manufacturing services. Amongst other products, the company produces viscosity improvers. They serve to modify or improve the viscosity to achieve the desired fluidity of liquids for instance for engine oil and transmission oils for cars and trucks.

The company works for its customers according to the clients’ formula and under an agreement of secrecy. GADOT Group aims at the European market, the Middle East and Africa. The products are supplied and conveyed by water and by road.

In June 2016, GADOT Group celebrated its 50th anniversary in port of Ghent. The business was founded in 1966 and was run by various operators throughout the years, among them were Chevron, Texaco, Afton and ADPO. In 2010, the site was acquired by GADOT Group and integrated in its European logistical activities.